How do I choose a Cold Works D2 tool steel?

In the intricate world of metalworking, selecting the appropriate tool steel is a pivotal decision that can significantly impact the quality, durability, and overall success of your project. When it comes to Cold Works applications, Yongxiang's D2tool steel (also known as AISI X153CrMo12 or 1.2379) stands out as a premier choice for its exceptional hardness, wear resistance, and toughness. This guide will empower you to make an informed decision when choosing Yongxiang's D2 tool steel for your specific needs.

Understanding D2 Tool Steel

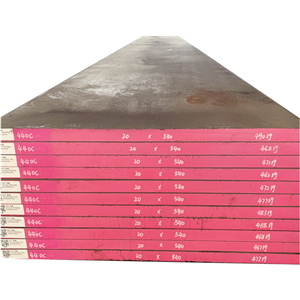

D2, classified under the Cr12Mo1V1 category, is a high-carbon, high-chromium cold work tool steel renowned for its exceptional resistance to wear and abrasion. Its chemical composition, including molybdenum and vanadium additions, enhances its ability to withstand intense stresses and maintain sharp cutting edges even under heavy loads. Yongxiang's D2 tool steel adheres to the strict international standards (AISI, DIN, etc.), ensuring consistency in quality and performance.

Why Choose Yongxiang D2 Tool Steel?

Durability & Wear Resistance: Ideal for applications requiring resistance to wear and tear, Yongxiang's D2 tool steel can withstand prolonged use without significant degradation. This makes it a perfect fit for punches, dies, cutting blades, and other tools that endure high levels of abrasion.

Excellent Hardness: Through proper heat treatment, Yongxiang D2 can achieve exceptional hardness levels, allowing it to maintain a sharp cutting edge for extended periods. This feature is crucial in applications where precision and longevity are paramount.

Toughness & Resistance to Chipping: Despite its impressive hardness, D2 tool steel retains sufficient toughness to resist cracking or chipping under high-impact conditions. This balance of hardness and toughness is unique to D2 and highly sought after in demanding manufacturing environments.

Versatility: Yongxiang's D2 tool steel finds its way into a wide range of applications, from metal stamping and forming to plastic injection molding and even the creation of high-performance knives. Its versatility underscores its status as a go-to material for professionals across various industries.

Factors to Consider When Choosing Yongxiang D2 Tool Steel

Application Requirements: Consider the specific demands of your project, including the type of material being worked on, the degree of wear and tear, and the required precision.

Heat Treatment: Understand the recommended heat treatment protocols for Yongxiang D2 to achieve optimal hardness and performance.

Cost-Benefit Analysis: Evaluate the cost of Yongxiang D2 against its long-term benefits, such as increased tool life and reduced downtime.

Supplier Reputation: Choose a reputable supplier like Yongxiang, known for their consistent quality and customer support.

Choosing Yongxiang's D2 tool steel for your Cold Works applications is a strategic decision that can pay dividends in terms of enhanced tool performance, extended lifespan, and reduced costs. By understanding the unique properties of D2 steel and carefully considering your project's requirements, you can confidently select the right material to elevate your metalworking endeavors. Trust Yongxiang, a trusted name in the industry, to provide you with high-quality D2 tool steel that meets and exceeds your expectations.