440C GB 9Cr18Mo JIS SUS440C ASTM S44004 Stainless Steel

- :China

- :30-45 days

440C 9Cr18Mo SKD11 AISI D2 X153CrMo12 1.2379 Cr12Mo1V1 Tool Steel

1: 440C Steel Introduction

The main characteristics of 440C mold steel include excellent corrosion resistance, high hardness, and good wear resistance. 440C mold steel also has good processing performance and can achieve ideal hardness and wear resistance through heat treatment processes such as quenching and tempering. It can also be processed through conventional machining methods such as cutting, milling, and grinding, and is suitable for mold manufacturing of various shapes and sizes. 440C mold steel has become the preferred material for many high-end mold and tool manufacturing due to its excellent corrosion resistance, high hardness, and good wear resistance.

2: 440C Steel Equivalent

3: 440C Steel Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | V | Mo |

| 440C | 0.95~1.20 | ≤1.00 | ≤1.00 | ≤0.035 | ≤0.030 | 16.00~18.00 | - | 0.50 |

| D2 | 1.4-1.6 | 0.1-0.6 | 0.1-0.6 | 0.03 | 0.03 | 11-13 | 0.5-1.1 | 0.7-1.2 |

| 1.2379 | 1.45-1.6 | 0.15-0.6 | 0.2-0.6 | 0.03 | 0.03 | 11-13 | 0.7-1 | 0.7-1 |

| SKD11 | 1.4-1.6 | ≤0.40 | ≤0.60 | ≤0.03 | ≤0.03 | 11-13 | 0.2-0.5 | 0.8-1.2 |

4: 440C Steel Mechanical Properties

440C mold steel also has good processing performance and can achieve ideal hardness and wear resistance through heat treatment processes such as quenching and tempering. It can also be processed through conventional machining methods such as cutting, milling, and grinding, and is suitable for mold manufacturing of various shapes and sizes.

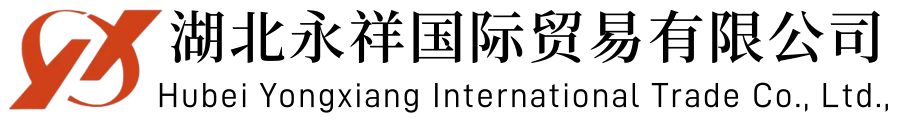

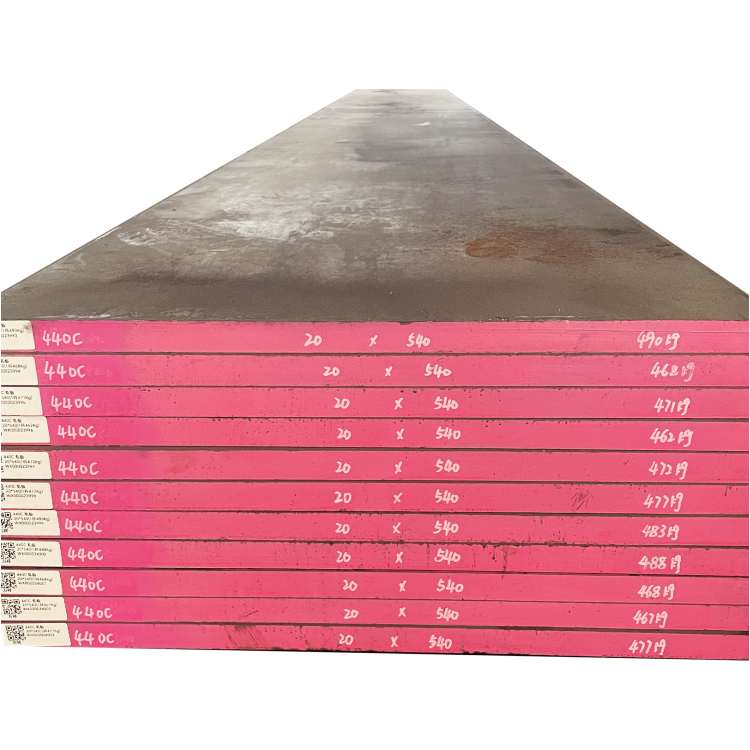

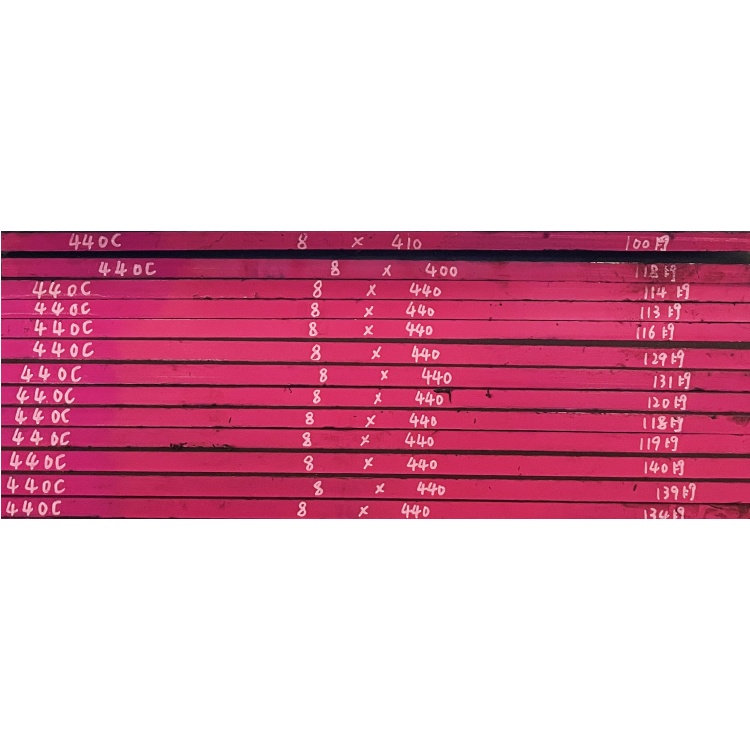

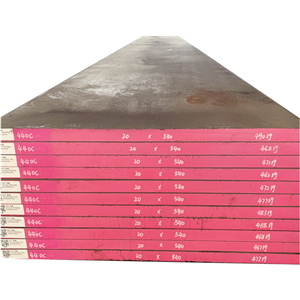

5: 440C Steel Overviews

| Size | Plate/Flat/Block | Thickness 6mm-500mm |

| Width 20mm-1000mm | ||

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | |

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | |

| Delivery condition | Forged; Hot rolled; Cold drawn | |

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | |

| Payment terms | T/T;L/C;/Money gram/ Paypal | |

| Trade terms | FOB; CIF; C&F; etc.. | |

| Delivery time | 50 days | |

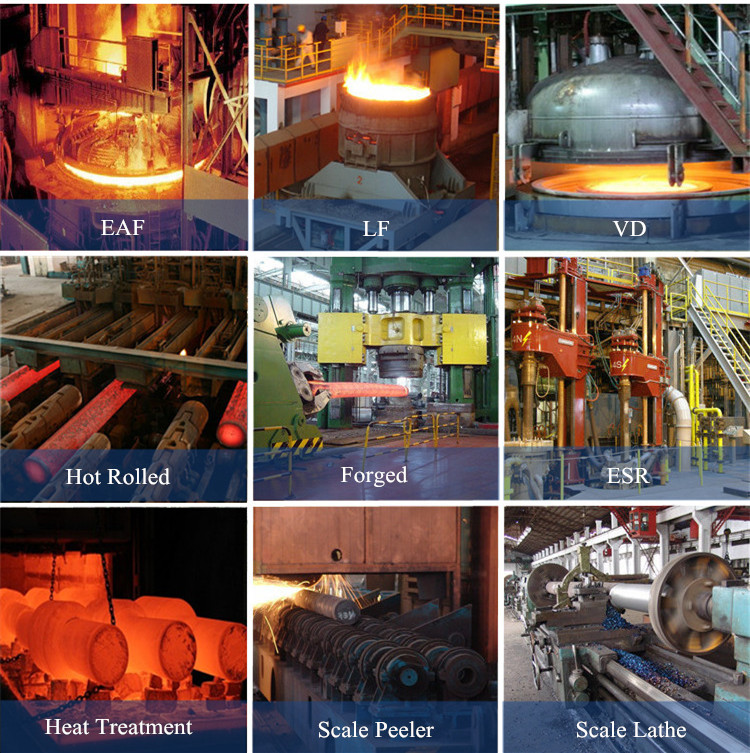

6: Delivery Condition

For hot forged bar, usually the delivery condition is hot forged, annealed rough turned/Black surface.

For hot rolled bar, usually the delivery condition is hot rolled, annealed, Black surface.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

Company Main Products:(If you do not find the product you need, please contact us)

Cold Work Tool Steel | DIN 1.2080,DIN 1.2379,DIN 1.2436,DIN 1.2210,JIS SKS3,AISI O2 |

Hot Work Tool Steel | H13,DIN 1.2714,DIN 1.2767,DIN 1.2344(H13),DIN 1.2713 |

Plastic Mould Steel | P20,P20+S,P20+Ni,DIN 1.2083,DIN 1.2316,DIN 1.2085 |

Stainless Steel | 316L,201,301,304,316,410,420,430,431,440C,SUS630(DIN1.4542) |

High Speed Steel | DIN 1.3343(M2),DIN 1.3243(M35),DIN 1.3247,DIN 1.3265 |

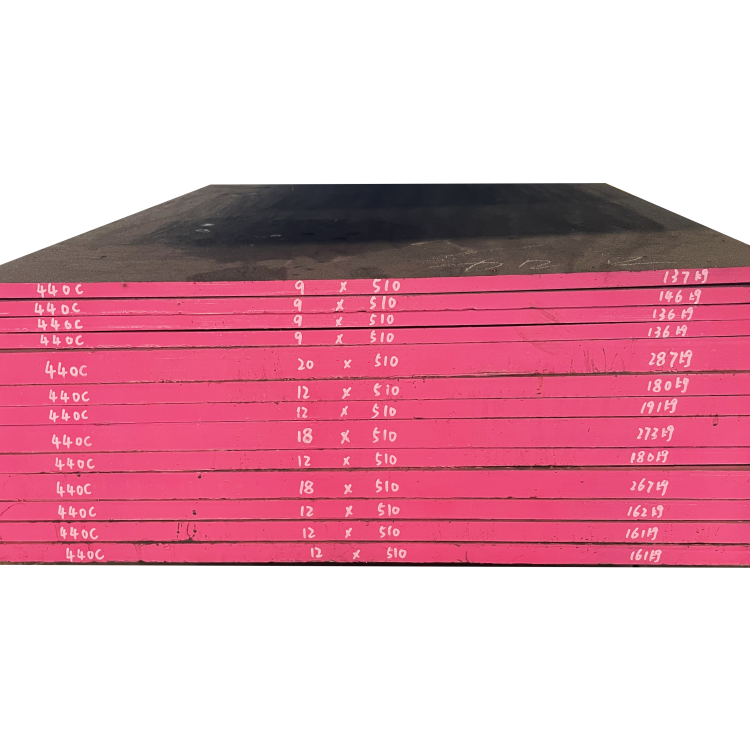

The company has newly purchased the latest automated 850 rolling mill, heat treatment furnace, CNC double head milling machine, precision grinder, CNC gantry precision milling machine and its supporting equipment. We can produce mold steel products with thicknesses ranging from 8mm to 80mm and a maximum width of 810mm. Application and mold manufacturing, electronics, electrical appliances, machinery, aerospace, hardware, building materials, automotive and other fields.

The latest automated 850 rolling mill production line has a total length of 138 meters and 127 motors. So far, this production line is the only one in the country and is one of the most advanced equipment at present. And compared to traditional production lines, this production line not only improves production efficiency, product quality, production stability, and safety, but also reduces labor demand, achieving energy-saving and environmental protection effects. And have the ability to adapt to different production needs and continuously optimize.

Q1:Are you trading company or manufacturer ?

We are professional manufacturer for many years. we can provide a wide range of steel products.

Q2.What is your lead time?

Depends actual order,around 45-50 days,or negotiation.

Q3.Can you supply sample?

Yes,we can.Sample fee according to your size.

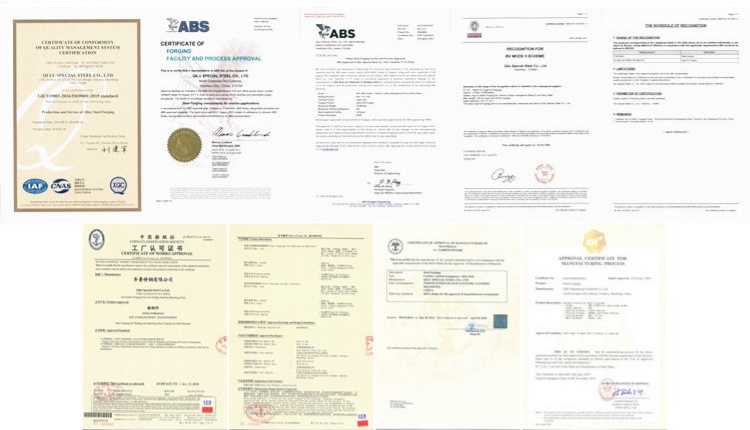

Q4:What certificates do you have?

ISO, ABS, BV, CCS, Dnv, Lr, Gl, Mill Certificate

Q5: How can I get your quotation as soon as possible?

The email and fax will be checked within 24 hours,meanwhile,the Skype,Wechat and WhatsApp will be online in 24 hours.Please send us your requirement,we will work out a best price soon.