What Is O1 Tool Steel Grade

Tool steels are a class of metal alloys specifically designed for applications requiring hardness, wear resistance, and strength. Among these, O1 tool steel stands out for its versatility and performance. This article delves into the characteristics of O1 tool steel, discussing its composition, properties, and typical uses, with a special focus on the Yongxiang brand.

What Is O1 Tool Steel Grade?

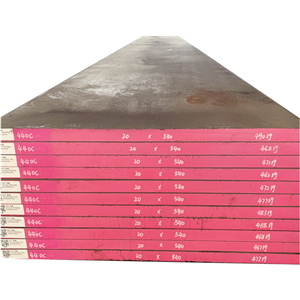

O1 tool steel is a common type of cold-work tool steel characterized by its high wear resistance and ability to maintain sharp edges. It is composed primarily of carbon, with additional alloying elements such as chromium, manganese, and tungsten. The specific composition of O1 can vary slightly depending on the standard it adheres to, such as GB 9CrWMn in China, DIN 1.2510 in Germany, JIS SKS3 in Japan, and ASTM 2140 in the United States.

Properties of Yongxiang O1 Tool Steel

Yongxiang, a reputable manufacturer of tool steels, produces O1 tool steel that meets international standards, ensuring consistent quality and performance. The following are key properties of Yongxiang

O1 tool steel:

Hardness: O1 tool steel can be heat-treated to achieve a hardness of 60-66 HRC, making it ideal for applications requiring a sharp edge and resistance to abrasion.

Toughness: Despite its hardness, O1 maintains a degree of toughness, which helps resist chipping and breaking under impact.

Wear Resistance: The alloying elements contribute to the steel's ability to resist wear, extending the life of tools made from this material.

Machinability: O1 is relatively easy to machine in its annealed state, although it becomes harder to machine post-hardening.

Applications of Yongxiang O1 Tool Steel

Due to its desirable properties, O1 tool steel finds applications in various industries:

Cutting Tools: O1 is commonly used for making drills, taps, reamers, and milling cutters due to its ability to hold a sharp edge and resist wear.

Molds: In the plastic injection molding industry, O1 tool steel is used for parts of molds that require high hardness and wear resistance.

Stamping Dies: For metal stamping operations, O1 tool steel is utilized for dies and punches because of its toughness and wear resistance.

Precision Components: In mechanical engineering, O1 tool steel is employed for making precision components such as gears and punches that need to maintain dimensional accuracy over time.

Manufacturing Process of Yongxiang O1 Tool Steel

The production of Yongxiang O1 tool steel follows a rigorous process to ensure uniformity and quality:

Smelting: The raw materials are melted in an electric furnace to achieve the desired chemical composition.

Pouring: The molten steel is poured into ingots or continuous casting billets.

Hot Working: The ingots are hot worked to form bars or other shapes.

Heat Treatment: The steel undergoes heat treatment processes such as annealing, hardening, and tempering to achieve the required mechanical properties.

Quality Assurance: Yongxiang performs thorough inspections and tests to verify that the finished product meets the specified standards.

Yongxiang O1 tool steel exemplifies the balance between hardness and toughness required for demanding industrial applications. Its widespread use across industries speaks to its effectiveness and reliability. Whether for cutting tools, molds, or precision components, Yongxiang O1 tool steel delivers the performance needed to meet the challenges of modern manufacturing. By understanding the properties and applications of O1 tool steel, engineers and manufacturers can make informed decisions when selecting materials for their projects.