What Is Tool Steel

Tool steel is a category of steel that is designed to maintain its shape and hardness at high pressures and temperatures. This makes it ideal for a variety of industrial applications where durability and strength are paramount. Within the broad spectrum of tool steels, Yongxiang offers a range of products, including mold steel, impact-resistant tool steel, and alloy tool steel, each tailored to specific needs and performance requirements. Let's delve deeper into what these types of tool steels are and how they benefit various industries.

What is Tool Steel?

Tool steel is a class of carbon and alloy steels that are well-suited for tool manufacturing. Its properties include hardness, wear resistance, and toughness, which are critical for cutting, forming, and pressing materials in manufacturing processes. The composition of tool steel varies depending on the application, with different alloys added to achieve desired characteristics such as heat resistance or corrosion resistance.

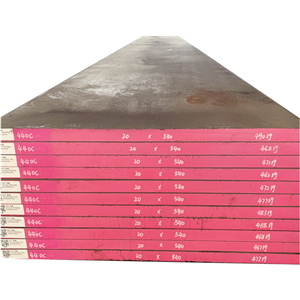

Mold Steel: Yongxiang's Contribution

Mold steel, a subset of tool steel, is specifically designed for the creation of molds used in injection molding, die casting, and other manufacturing processes. Yongxiang's mold steels are engineered to withstand the rigors of repeated use and the high temperatures associated with molten plastics and metals. These steels are known for their uniformity, which ensures consistent performance and reduces the likelihood of defects in the final product. The addition of chromium and molybdenum in Yongxiang's mold steels enhances their corrosion resistance and hardenability, making them a reliable choice for manufacturers seeking long-lasting and high-quality molds.

Impact Resistant Tool Steel: Durability and Strength

Impact-resistant tool steel is a type of tool steel that is optimized for applications requiring exceptional toughness and resistance to shock and impact. Yongxiang's impact-resistant tool steels are characterized by their ability to absorb energy without fracturing, making them ideal for tools and machinery subjected to heavy loads and dynamic forces. The inclusion of vanadium and tungsten in the alloy composition increases the wear resistance and toughness of the steel, allowing tools made from it to maintain their edge longer and resist chipping and breaking even under severe conditions.

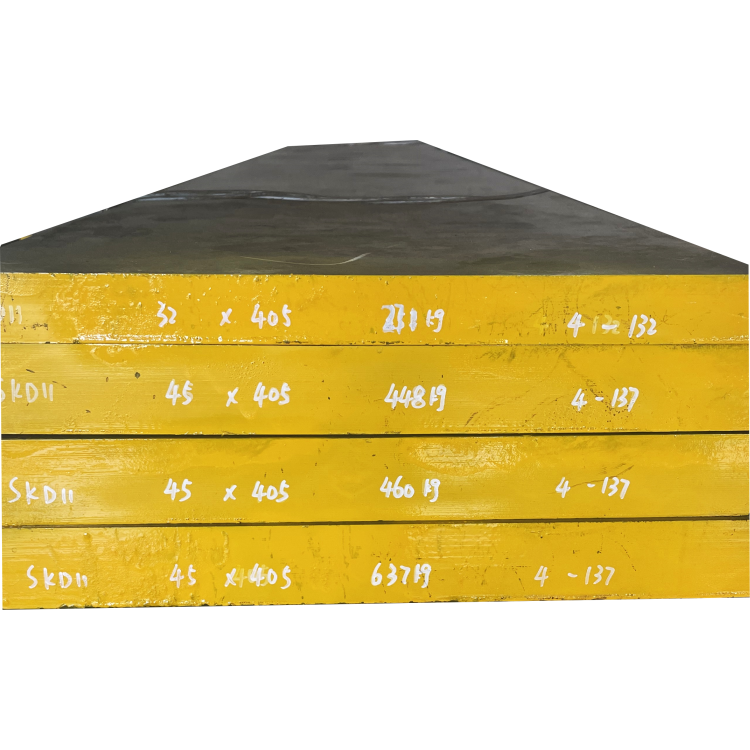

Alloy Tool Steel: Versatility and Performance

Alloy tool steel is a category of tool steels that contain one or more alloying elements, such as tungsten, molybdenum, chromium, or vanadium, which impart specific properties to the steel. Yongxiang's alloy tool steels are designed to offer a balance of hardness, wear resistance, and toughness, making them suitable for a wide range of applications, from cutting tools to punches and dies. The addition of these alloying elements improves the overall performance of the steel, enhancing its ability to hold an edge, resist wear, and maintain its properties at elevated temperatures.

Tool steel is a fundamental component in the manufacturing sector, serving as the backbone for countless tools and machines. Yongxiang's commitment to quality and innovation is reflected in its range of tool steels, including mold steel, impact-resistant tool steel, and alloy tool steel. By understanding the specific needs of its customers and tailoring its products to meet those requirements, Yongxiang continues to set the standard for excellence in the industry. Whether you're looking for a material that can withstand the harsh conditions of metalworking or a steel that can deliver consistent performance in the demanding environment of plastics manufacturing, Yongxiang's tool steels are engineered to deliver the reliability and performance you need.